The Double Check Isolation Valve is a specialized backflow prevention device designed to protect potable water systems from contamination. It consists of two independent check valves arranged in series, providing redundant protection. This valve is typically used in commercial, industrial, and municipal water supply lines, especially where there is a moderate hazard level.

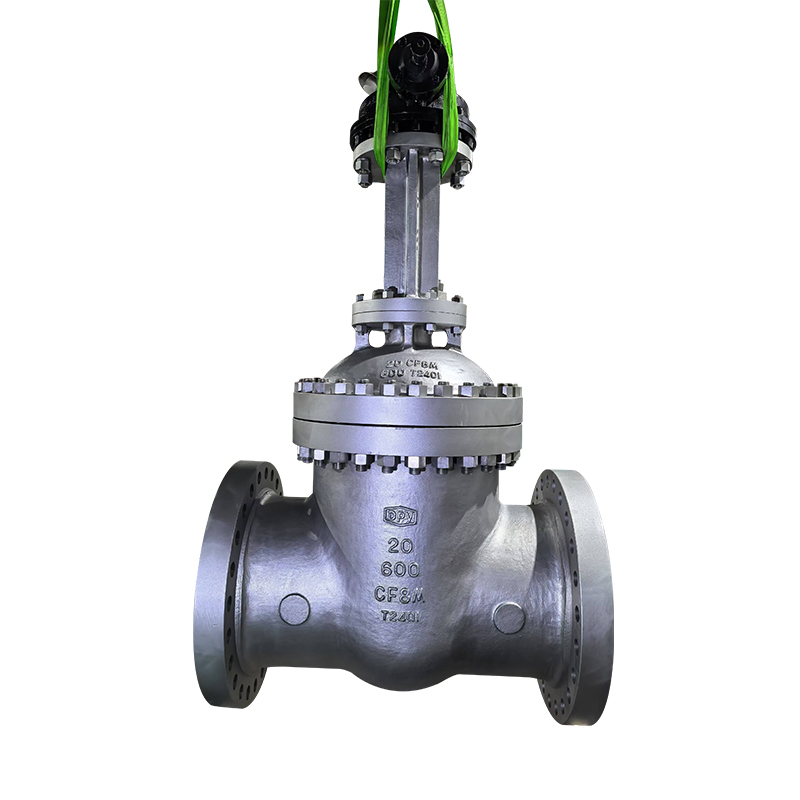

One of the key features of the Double Check Isolation Valve is the use of advanced materials in its construction. Common materials include ductile iron, stainless steel, and high-performance thermoplastics, each selected based on corrosion resistance, pressure rating, and fluid compatibility. These materials ensure durability and a long service life even in demanding conditions.

The design incorporates modular construction, allowing for ease of maintenance and repair. Many models include test cocks and shutoff valves for performance monitoring. The dual-check design ensures that even if one valve fails, the second still provides backflow protection.

Compact size, ease of installation, and minimal pressure loss make the Double Check Isolation Valve suitable for a range of applications, including irrigation systems, fire protection lines, and commercial plumbing. The ability to isolate the valve also simplifies inspections and servicing, reducing downtime.

The Check Valve for Irrigation System plays a crucial role in preventing water from flowing backward into the main supply line. This is particularly important in agricultural and landscape irrigation, where fertilizers or chemicals are sometimes introduced into the water system. By installing a check valve, contamination risks are minimized, and the integrity of the water supply is maintained.

Typically, a Check Valve for Irrigation System is placed near pumps, sprinkler heads, or backflow devices to ensure one-way flow. These valves are often made of materials like PVC, brass, or stainless steel, which resist corrosion and require little maintenance. The design is generally simple, relying on a spring-loaded mechanism or a flap that closes when reverse flow is detected.

One of the main advantages of using a Check Valve for Irrigation System is system efficiency. When pumps are turned off, the valve helps retain water in the pipeline, reducing the time required to build pressure during the next cycle. This contributes to lower energy use and consistent irrigation performance.

In drip irrigation systems, the check valve prevents the backward siphoning of water that might carry soil or debris into the lines, preserving system cleanliness and preventing clogs. For larger agricultural systems, check valves also help protect booster pumps and other equipment from damage caused by pressure fluctuations.

Simple installation, long service life, and low maintenance make the Check Valve for Irrigation System an essential component for both small-scale gardening and large-scale agricultural applications. Its contribution to safety, water efficiency, and equipment protection is well recognized.

The Dual Flap Check Valve is designed to control the direction of fluid flow while pressure loss and preventing backflow. Featuring two spring-loaded flaps that close independently when flow reverses, this valve is ideal for systems requiring quick shutoff and reliable sealing.

Commonly used in wastewater treatment, chemical processing, and industrial water systems, the Dual Flap Check Valve is built to handle high flow rates and moderate to high pressure. The dual-flap design provides a more balanced flow profile compared to single-flap valves, reducing water hammer and improving valve longevity.

Manufactured from materials such as ductile iron, carbon steel, or stainless steel, the Dual Flap Check Valve offers strength and chemical resistance. Internal components may include rubber or elastomer seats to ensure tight sealing, even under low-pressure conditions. Many models also feature a wafer or lug-type body for compact installation between flanges, saving space and simplifying maintenance.

Safety is a key consideration in the design of the Dual Flap Check Valve. The rapid response of the flaps during reverse flow reduces the risk of pressure surges, protecting pipelines and connected equipment. The valve's structure also limits moving parts, lowering the chance of mechanical failure.