The floating ball check valve is a reliable solution for preventing reverse flow in piping systems. This valve operates automatically and is commonly used in water supply networks, drainage systems, and industrial processes where backflow prevention is necessary. Its simple yet effective design ensures that fluid flows in one direction only, contributing to system safety and operational consistency.

The primary mechanism involves a hollow or solid ball that moves within the valve body. When fluid flows in the intended direction, pressure lifts the ball away from the valve seat, allowing passage. If the flow reverses, the ball returns to the seat, blocking the passage and preventing backflow. The design relies on both gravity and fluid pressure to position the ball correctly.

Floating ball check valves are often made from durable materials such as brass, stainless steel, or plastic, depending on the application's chemical and temperature requirements. Their internal simplicity makes them less prone to mechanical failure and relatively easy to maintain.

Commonly installed in vertical or horizontal lines, these valves are selected based on flow rate, pressure requirements, and media type. They are particularly effective in systems where flow interruptions can cause process disruptions or equipment damage.

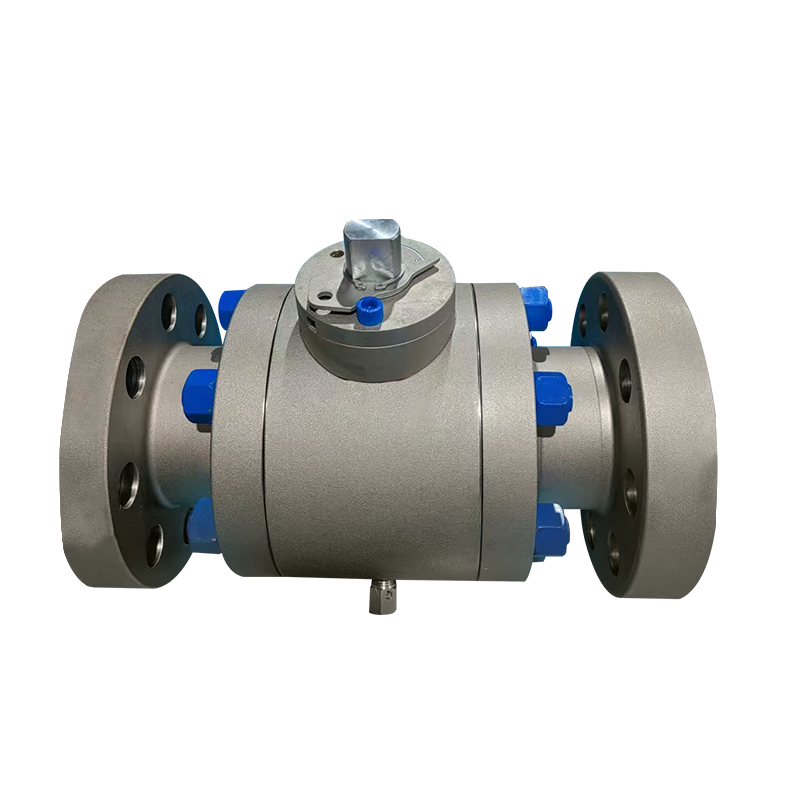

The carbon steel floating ball valve is a versatile choice for medium to high-pressure fluid systems across various industrial sectors. It features a ball that is suspended within the valve body and pressed against the downstream seat by fluid pressure to achieve a tight seal. This type of valve is widely used in the chemical, petroleum, and gas industries, where durability and sealing performance are important.

Carbon steel is the preferred material due to its mechanical strength, impact resistance, and ability to perform under higher pressure conditions. It also offers a balance between cost-efficiency and structural integrity, especially when dealing with non-corrosive or mildly corrosive media. For corrosive environments, internal coatings or seat materials such as PTFE are added to enhance resistance.

The floating ball design provides reliable sealing through simple construction. The ball is not fixed by a trunnion but is allowed to move slightly under pressure, pressing firmly against the seat to close the flow path. This self-aligning action ensures effective shutoff, particularly in applications where moderate pressure differentials are common.

Another advantage of carbon steel floating ball valves is their ease of automation. They are often fitted with actuators for remote operation in process control systems. Maintenance is straightforward due to their compact body design and accessible internals.

In summary, carbon steel floating ball valves are known for their mechanical reliability, adaptable sealing capability, and operational efficiency. Their combination of strong materials and practical engineering makes them suitable for a wide range of industrial applications.

High temperature float valves are engineered for environments where conventional valve materials and seals would degrade or fail. These valves are typically found in steam systems, hot water tanks, boilers, and heat-intensive industrial processes. Their main function is to automatically regulate fluid levels while withstanding elevated temperatures for prolonged periods.

The core of the valve is a float mechanism that rises and falls with the liquid level. As the float moves, it opens or closes the valve to maintain a pre-set level within the tank or vessel. What differentiates a high temperature float valve from standard models is the use of heat-resistant materials, such as stainless steel bodies and reinforced seals or seats made from materials like graphite or high-temperature elastomers.

These valves must retain their structural integrity and responsiveness despite exposure to heat, pressure, and often chemically aggressive media. Therefore, precision engineering is required to ensure the moving parts remain functional and the sealing surfaces do not deform or wear prematurely.